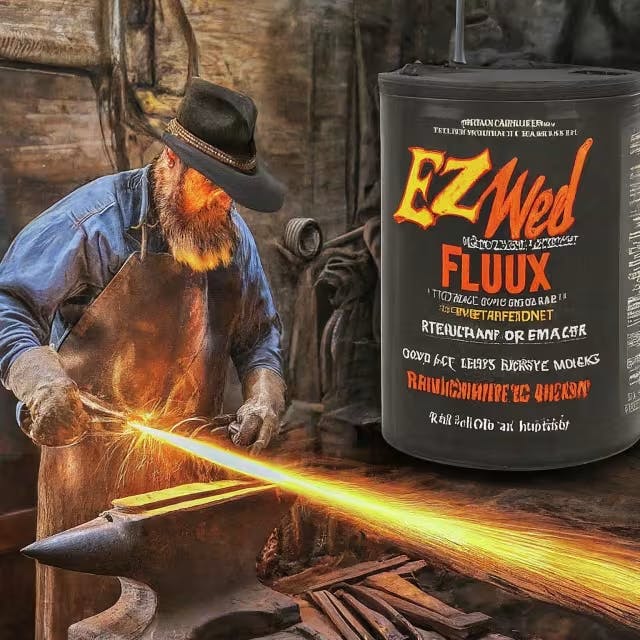

EZ Weld Flux: Blacksmith's Choice

Abana Chapter

March 27, 2024

In the world of blacksmithing, choosing the right flux for welding is as much an art as it is a science. Amidst the myriad of options available, EZ Weld Flux emerges as a preferred choice for many professionals, combining traditional techniques with modern efficiency. This article dives into the nuances of EZ Weld Flux, exploring why it stands out in the blacksmith community for its reliability in achieving the best welding temperatures and favorable outcomes in metalwork projects.

Key Takeaways

EZ Weld Flux is highly regarded in the blacksmith community for its effectiveness in achieving optimal welding temperatures and quality metalwork outcomes.

Its popularity among professionals stems from its blend of traditional and modern blacksmithing techniques.

The main benefits of EZ Weld Flux include improved welding quality, efficiency, and versatility in various metalworking projects.

Proper usage of EZ Weld Flux can significantly enhance the welding process, contributing to cleaner and stronger joins.

The development of EZ Welding Technology represents a significant evolution in metal joining methods, offering a modern solution that holds true to the art of blacksmithing.

Compared to other metal joining methods, EZ Weld Flux offers a unique combination of reliability, performance, and ease of use, making it a preferred choice for many blacksmiths.

What Is EZ Weld Flux and Why Do Blacksmiths Prefer It?

EZ Weld Flux stands as a trusted ally in the blacksmith's workshop, celebrated for its ease and efficiency in creating durable metal links. It cuts through the confusion of choosing the right flux, making it a straightforward choice for both novices and seasoned professionals. The allure of EZ Weld Flux lies in its ability to clean and protect metal surfaces during welding, ensuring a strong, oxidation-free bond - a vital step for any successful metal project.

Key Advantages of EZ Weld Flux:

Ease of Application: Say goodbye to complex fluxing methods. EZ Weld Flux's simple application process welcomes blacksmiths of all skill levels, allowing more time to focus on the art of metalwork.

Safety First: Working safer means working smarter. EZ Weld Flux is formulated to produce less harmful smoke, making for a healthier work environment.

Versatility: Whether you're joining iron, steel, or nickel, EZ Weld Flux has got you covered. Its compatibility with a wide range of metals adds to its appeal and practicality in a variety of projects.

For those delving into knife making, a craft that demands precision and strength, combining EZ Weld Flux with essential blade crafting tools can elevate your craft, ensuring that each piece isn't just beautiful, but built to last.

Remember, adopting EZ Weld Flux into your repertoire is more than a choice; it's embracing a blend of tradition and innovation to enhance your blacksmithing projects. Each weld tells a story of quality and craftsmanship, and with EZ Weld Flux, those stories become legends in the metalworking community.

The Main Benefits of EZ Weld Flux for Metalwork

When it comes to metalwork, particularly in blacksmithing, choosing the right flux can make a world of difference in the quality and efficiency of your work. EZ Weld Flux emerges as the preferred choice among blacksmiths for several compelling reasons. It not only cleans the metal surfaces, preparing them for welding, but also prevents oxidation during the heating process. This double-action capability ensures that welds are cleaner, stronger, and more reliable over time.

EZ Weld Flux's ease of use is another significant advantage. Unlike some alternative fluxes that require meticulous application methods, this flux can be easily applied, making it accessible to blacksmiths of all skill levels. It's conducive to both professional projects and hobbyist endeavors, streamlining the welding process without compromising on quality.

Safety is a paramount concern in any form of metalwork, and using EZ Weld Flux contributes to a safer working environment. Its formulation reduces the amount of toxic smoke released during welding, hence minimizing health risks associated with inhalation.

Finally, compatibility is where EZ Weld Flux truly shines. It works seamlessly with a wide range of metals, including but not limited to iron, steel, and nickel, making it a versatile addition to any blacksmith's toolkit. For those diving deeper into the craft, exploring essential welding supplies further enhances your capability to undertake diverse projects with confidence.

Choosing EZ Weld Flux not only elevates the quality of your metalwork but also enriches your blacksmithing experience with its user-friendly properties, safety benefits, and broad metal compatibility. It's a choice that aligns with both tradition and modern blacksmithing needs, solidifying its status as the go-to flux for professionals and hobbyists alike.

How to Use EZ Weld Flux for Optimal Results

Achieving the best results with EZ Weld Flux requires a straightforward approach that ensures strong, durable welds every time. Begin by thoroughly cleaning the surfaces to be joined. Remove any rust, paint, or debris. This step is crucial as it allows the flux to work directly on the metal, ensuring a cleaner weld.

Apply a small amount of EZ Weld Flux onto the metal surfaces you're joining. A thin, even layer is all that's needed. Over-application can lead to unnecessary waste and might even affect the weld quality.

Heat is a critical component of the welding process, and proper application is key. As you heat the metal, the flux will become active, cleaning the metal surface and facilitating the welding process. The flux's main job is to prevent oxidation, which can weaken the weld. Keep the heat consistent and watch for the flux to indicate when the metal is ready for joining.

After welding, cleaning any residual flux off the project is essential. While EZ Weld Flux is designed for ease of use, leftover material can affect the finish and longevity of the weld.

For beginners and experts alike, managing temperature and timing can initially seem challenging. Practice on scrap pieces before starting your main project. This hands-on experience is invaluable and will build confidence in judging the right moment to start and finish your welds.

Step | Action | Tips |

1. Clean | Remove rust, paint, debris | Clean surfaces ensure better adhesion |

2. Apply | Put a small amount of flux | A thin layer is sufficient |

3. Heat | Heat the metal until flux activates | Watch for the flux's signal |

4. Weld | Join the metals together | Ensure consistent heat application |

5. Clean again | Remove any leftover flux from the weld | This ensures a clean finish |

Remember, like any skill, perfection comes with practice. EZ Weld Flux is a tool designed to make the learning curve smoother and the welding process more manageable. For more detailed insights on enhancing your welding technique with EZ Weld Flux, explore this guide on advanced welding techniques.

Exploring the History of EZ Welding Technology

Taking a trip down memory lane to uncover the origins of EZ Weld flux is like stepping back in time to explore a significant development in the world of blacksmithing and metalworking. For many years, artisans have searched for ways to seamlessly and robustly connect metals together. EZ Weld flux stepped onto the scene and changed the game, offering a reliable method for forging strong, lasting connections between pieces of metal.

This cutting-edge flux quickly caught the eye of experts for its ability to fend off oxidation during the welding process. As blacksmiths and metalworkers deepened their understanding of just how essential good quality flux is in joining metals, EZ Weld flux became the go-to choice for many, thanks to its consistent performance and superior quality.

Selecting the right flux for the job is key to achieving a solid weld. This is a hot topic among discussions about metal joining methods, where the emphasis on using premium materials can't be overstated. For those looking to gain more insight into this area, a detailed exploration is available here, offering an in-depth look at different types of flux and how they're used.

EZ Weld flux is in a league of its own, thanks to its custom blend formulated specifically for the needs of blacksmithing projects. Its mixture is the secret to clean, robust welds, making it an essential tool for both seasoned professionals and enthusiastic hobbyists. Its continued popularity highlights its efficacy and dependability across various metalworking projects.

Metal crafting is an intricate art that requires not just talent and precision, but also the right tools and materials. EZ Weld flux has established itself as a reliable ally in this creative endeavor, seamlessly linking tradition with modern techniques through its steadfast performance and utility.

Comparing EZ Weld Flux to Other Metal Joining Methods

EZ Weld Flux stands out as a reliable option for blacksmiths due to its adaptability and effectiveness in creating strong metal joints. Unlike other metal joining methods, EZ Weld Flux offers a unique blend of simplicity and efficiency. For those who prefer traditional or alternative metal joining techniques, exploring the broader landscape of welding compounds for strong metal bonds can provide valuable insights.

Joining Method | Ease of Use | Strength of Bond | Recommended for |

EZ Weld Flux | High | High | General blacksmithing |

Soldering | Medium | Medium | Detailed metalwork |

Brazing | Medium | High | Structural applications |

Welding (MIG/TIG) | Low | Very High | Professional projects |

EZ Weld Flux doesn't require the high temperatures of welding, making it accessible for beginners while still strong enough for most projects. It's an excellent choice for those who are looking for a balance between ease of use and the durability of the bond. EZ Weld Flux stands out as the blacksmith's choice, thanks to its unparalleled ability to provide clean, strong, and oxidation-free welds across a variety of metals. Its user-friendly application process and proven effectiveness in enhancing metal projects make it an indispensable tool in metalwork. By choosing EZ Weld Flux, blacksmiths, whether novice or professional, are ensuring the highest quality and reliability in their craft, solidifying its revered status in the metalworking community.

Frequently Asked Questions

Why is EZ Weld Flux the preferred choice among blacksmiths for metal joining?

EZ Weld Flux is the preferred choice among blacksmiths for its ease of use, effectiveness in preventing oxidation, and compatibility with a wide range of metals. Its simple application process appeals to all skill levels, contributing to a safer working environment by producing less harmful smoke. These features, combined with its ability to ensure cleaner, stronger welds, make EZ Weld Flux a go-to solution for both novices and seasoned professionals in metal joining projects.

How does EZ Weld Flux promote a safer working environment?

EZ Weld Flux promotes a safer working environment primarily through its specialized formulation that generates less harmful smoke during the welding process, thus significantly reducing the inhalation of toxic fumes. It simplifies the application process, allowing users to maintain a cleaner, more organized workspace, which inherently decreases the risk of accidents. Furthermore, its compatibility with a wide range of metals ensures reliable joints, minimizing the need for reworks that could expose workers to safety hazards.

What types of metals is EZ Weld Flux compatible with for welding projects?

EZ Weld Flux is designed for compatibility with a broad range of metals, ensuring its versatility in various welding projects. It can be effectively used with:

Iron

Steel

Nickel

This compatibility range makes EZ Weld Flux a practical choice for different applications, from general blacksmithing tasks to more specialized metalwork like knife making, emphasizing its utility in both professional and hobbyist settings.

What are the key steps for achieving the best results with EZ Weld Flux?

Achieving optimal results with EZ Weld Flux involves cleaning the metal surfaces thoroughly before application, applying a thin, even layer of flux, and ensuring consistent heating during the welding process. It's also essential to remove any residual flux after welding to maintain the integrity and appearance of the weld. Practice and experience will further enhance skill and confidence in using EZ Weld Flux for a variety of metal joining projects.

How has EZ Weld Flux influenced the tradition and innovation in metalworking?

EZ Weld Flux has revolutionized metalworking by merging tradition and innovation through its ease of application, safety enhancements, and versatility with various metals. Its simple yet effective formula enables blacksmiths of all skill levels to achieve strong, oxidation-free bonds, ensuring both the art and science of metalworking progress. By promoting healthier work conditions and accommodating a broad range of projects, EZ Weld Flux stands as a pivotal tool that uplifts the craft into modernity while respecting its historical roots.